Email: admin@yeeshine-tech.com WhatsApp: +86-13712868936

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-11-28 Origin: Site

Injection molding plays a vital role in manufacturing precise plastic parts for various industries, including automotive and medical. Choosing the right mold type, whether single-cavity or multi-cavity, is crucial for balancing cost, quality, and efficiency.

In this article, we will compare Single-Cavity vs. Multi-Cavity injection molding, highlighting their unique benefits, applications, and when to use each one.

A Single-Cavity Mold is designed to produce one part per injection cycle. This type of mold is typically used for smaller production runs, prototypes, or when producing large, intricate parts. The primary advantage is the level of precision it offers since there is only one part to manage during each cycle.

Single-cavity molds are ideal for industries where precision is essential, such as medical devices, aerospace, and automotive components. Due to its simplicity, the mold design and tooling requirements are less complex, resulting in lower initial costs compared to multi-cavity molds. However, the cycle time for producing parts is longer, which can limit its use for high-volume production.

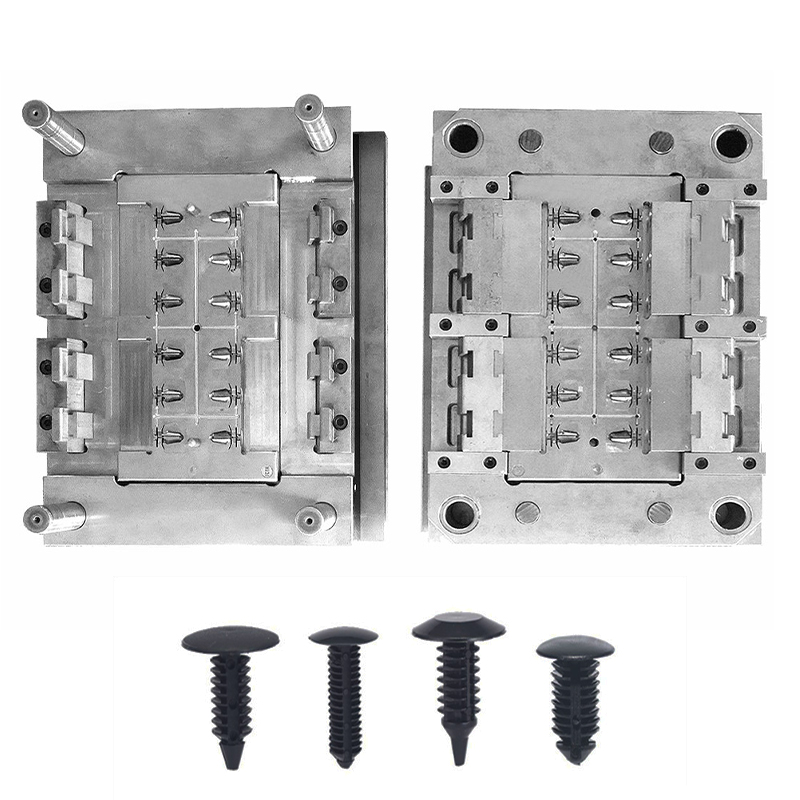

In contrast, Multi-Cavity Molds contain multiple cavities within a single mold, allowing several parts to be produced simultaneously during one cycle. This is especially useful for high-volume production, as it significantly boosts production efficiency and reduces the cost per part.

Multi-cavity molds are commonly used in industries that require mass production of identical parts, such as consumer goods, packaging, and automotive manufacturing. Although the upfront investment in tooling is higher, the reduced cost per unit makes multi-cavity molds highly cost-effective for large-scale production.

Family molds are a variation of multi-cavity molds designed to produce multiple different parts in one cycle. Unlike multi-cavity molds that produce identical parts, family molds create parts that are part of a larger assembly, such as different components of an electronic device.

Family molds offer unique benefits, especially for manufacturers seeking to streamline production processes by combining multiple parts into one cycle. However, the design and maintenance of family molds are more complex, as each cavity needs to accommodate parts with different shapes and sizes, requiring careful design to ensure uniform filling and cooling.

The Single-Cavity Mold produces one part per cycle, making it less efficient for high-volume production. On the other hand, Multi-Cavity Molds allow multiple parts to be produced simultaneously, increasing production efficiency. The more cavities within the mold, the more parts can be produced in a given cycle, leading to a faster overall production time.

However, the increase in efficiency comes at the cost of mold complexity. Multi-cavity molds require careful attention to material flow and cooling to ensure uniform production across all cavities.

While Single-Cavity Molds can offer more precise control over each individual part, Multi-Cavity Molds are designed to produce identical parts at a high rate. Consistency is key in high-volume production, and multi-cavity molds excel at maintaining uniformity in product quality, provided the mold is well-designed.

In contrast, any defects in one cavity can affect the final product's quality in multi-cavity molds, as all cavities must fill uniformly. This requires more advanced tooling and design to ensure all parts meet the same quality standards.

Single-Cavity Molds are simpler in design, requiring less intricate tooling and maintenance. The focus is on producing a single part per cycle, which reduces the complexity of ensuring even material flow and cooling.

Multi-Cavity Molds, however, are more complex. They require advanced engineering to balance material flow, cooling, and pressure across multiple cavities. Maintenance can also be more costly and time-consuming due to the complexity of the mold and the need for precise adjustments to ensure consistency across all cavities.

Feature | Single-Cavity Mold | Multi-Cavity Mold |

Parts per Cycle | 1 | 2 or more |

Production Efficiency | Slower, lower output | Faster, higher output |

Initial Cost | Lower | Higher |

Cost per Part | Higher for large volumes | Lower for large volumes |

Design Complexity | Simpler, easier to design | More complex, requires precision |

Best for | Small runs, high-precision parts | Large-scale production of identical parts |

Quality Control | Easier to manage | Requires more attention to uniformity |

Single-cavity molds are perfect for small-scale production, prototyping, or custom parts. They are often used for limited production runs where precision and flexibility are more critical than speed. Since the mold is designed for just one part per cycle, changes or adjustments can be made more easily without affecting the entire production process.

For intricate designs or parts that require a high degree of precision, single-cavity molds are the preferred choice. The lack of multiple cavities means there is more control over the material flow and cooling, leading to better quality and fewer defects.

One of the key advantages of single-cavity molds is their lower initial cost compared to multi-cavity molds. Since the mold design is simpler and requires less material, the tooling cost is typically much lower. This makes single-cavity molds ideal for businesses with limited budgets or those in the early stages of product development.

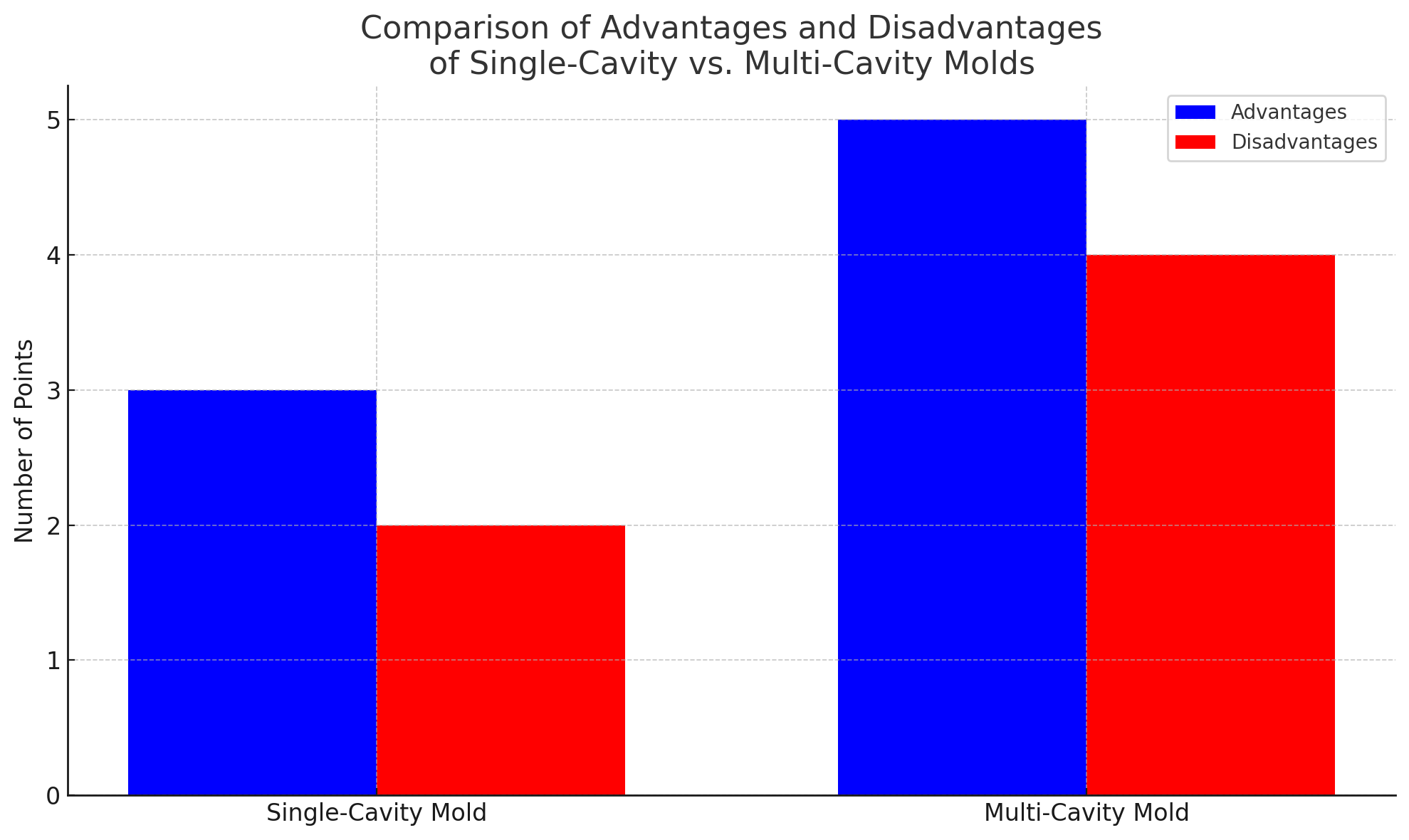

Mold Type | Advantages | Disadvantages |

Single-Cavity | Lower initial investment, high precision | Slower production, higher cost per part |

Multi-Cavity | High production efficiency, reduced cost per part | Higher initial cost, complex design & maintenance |

Multi-cavity molds are highly efficient for mass production. By producing several parts per cycle, manufacturers can significantly increase production output, making it ideal for high-demand products. This is particularly advantageous when producing large quantities of identical parts.

Though the upfront cost of multi-cavity molds is higher, the increased output per cycle leads to a lower cost per part. This cost-saving advantage becomes more significant as the production volume increases, making it a preferred choice for large-scale manufacturing.

Multi-cavity molds help ensure that all parts produced in a single cycle have the same quality and appearance. This uniformity is crucial for products that require consistent performance, such as automotive components or medical devices.

Single-cavity molds are best suited for situations where precision and flexibility take priority over production speed. Here are some scenarios where a single-cavity mold shines:

● Low-Volume Production or Prototyping: Single-cavity molds are an excellent choice for manufacturers working on small runs or prototypes. They allow for quick adjustments and are often used in the early stages of product development. Because the tooling costs are relatively low, they are ideal for businesses that need to test designs before committing to mass production.

● Parts with Complex Geometries or High Precision: When parts require intricate designs or highly precise dimensions, single-cavity molds are the go-to option. The simplicity of the mold design ensures that the focus remains on a single part, which minimizes the risks of defects or variations between parts. Industries that rely on tight tolerances, such as medical or aerospace, often prefer this method.

● Small Production Runs Where Flexibility is Essential: Single-cavity molds offer flexibility that is beneficial when product requirements change frequently. They are suitable for industries where product variants are required in small quantities, or when changes in the design need to be made during production. The ability to easily modify the mold and adjust designs allows manufacturers to cater to niche or specialized markets.

Multi-cavity molds, on the other hand, are designed for large-scale production and excel in environments where speed and cost-efficiency are paramount. Below are some common scenarios where multi-cavity molds are the best option:

● High-Volume Production of Identical Parts: Multi-cavity molds are ideally suited for situations where high quantities of identical parts need to be produced. Whether it’s for consumer products like bottle caps, automotive components, or medical supplies, multi-cavity molds can significantly increase the production output, reducing the cycle time and improving efficiency.

● Products Where Cost Per Part is a Major Consideration: When producing large volumes of parts, the cost per part is a key factor. Multi-cavity molds help reduce this cost by producing several parts in a single injection cycle. The initial investment in tooling may be higher, but as production volume increases, the cost per part decreases, making multi-cavity molds a highly cost-effective solution in mass production scenarios.

● Industries Requiring Speed and Efficiency: Industries such as consumer goods, packaging, and automotive manufacturing rely heavily on multi-cavity molds to meet high demand and ensure timely delivery. The ability to produce multiple parts in one cycle not only accelerates production times but also streamlines the entire manufacturing process, making it ideal for industries where speed and cost are critical to staying competitive in the market.

Mold Type | Best Use Cases |

Single-Cavity | Prototyping, low-volume production, complex/high-precision parts |

Multi-Cavity | High-volume production of identical parts, cost-efficiency |

In both Single-Cavity vs. Multi-Cavity molds, the material flow and cooling are crucial for producing high-quality parts. In multi-cavity molds, the material must flow evenly to all cavities, and the cooling system must be balanced to prevent warping or defects. For single-cavity molds, cooling is simpler but still critical for ensuring consistent quality.

Gate and runner systems play a vital role in controlling the flow of molten plastic into the mold cavities. A well-designed runner system ensures that all cavities fill evenly and reduces the risk of defects. Multi-cavity molds require more complex runner designs to ensure uniform filling, while single-cavity molds have simpler, more straightforward systems.

Mold design and tooling must be optimized for efficiency and cost. Multi-cavity molds are more expensive to design and manufacture due to their complexity, but the cost per part decreases as production volumes rise. Single-cavity molds are more affordable upfront but may not be cost-effective for high-volume production.

In summary, choosing between Single-Cavity vs. Multi-Cavity molds depends on production needs, part complexity, and budget. Single-cavity molds are ideal for small-scale production and high-precision applications. On the other hand, multi-cavity molds offer higher efficiency and cost savings for large-volume production. Manufacturers should assess their production goals and product requirements before selecting the right mold type.

For businesses like Yeeshine, which specialize in providing advanced molding solutions, understanding the advantages of both mold types is crucial. This ensures optimized production processes and cost efficiency for diverse applications.

A: The key difference lies in the number of cavities. Single-cavity molds produce one part per cycle, ideal for low-volume, high-precision work. Multi-cavity molds produce multiple identical parts per cycle, making them suitable for high-volume production with reduced cost per part.

A: Multi-cavity molds generally offer lower cost per part for large-volume production due to higher efficiency, though the initial investment is higher. Single-cavity molds are more cost-effective for small batches or prototypes.

A: Choose a Single-Cavity mold for small production runs, prototypes, or parts requiring high precision. Multi-Cavity molds are better suited for large-scale production where efficiency is key.

A: While Multi-Cavity molds are efficient, they require precise design to ensure uniformity across parts. Single-Cavity molds offer more control over quality but are slower.

A: Single-Cavity molds are simpler and easier to design, making them ideal for intricate parts. Multi-Cavity molds, though more complex to design, are efficient for high-volume production of identical parts.