Email: admin@yeeshine-tech.com WhatsApp: +86-13712868936

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-09-18 Origin: Site

Vacuum casting gives you a powerful solution for creating prototypes and small production runs with remarkable precision. You achieve rapid prototyping and cost-effective results, thanks to fast mold creation and affordable iteration.

Silicone molds form in days, not weeks.

You can cast parts within hours, test functionality, and move quickly to production.

Yeeshine Technology delivers transparent polyurethane resin prototypes and one-stop service.

| Service | Description |

|---|---|

| Vacuum Casting | Small mini transparent polyurethane resin parts |

| One-stop Service | From part design analysis to mass production |

| Confidentiality | Signed NDA for information security |

| Efficient Service | 24/7 support and quick response times |

You use vacuum casting to create detailed prototypes and small production runs with high accuracy. This process relies on a master mold, usually made with 3D printing, to capture every feature of your design. You then suspend the master in a casting box and pour liquid silicone around it. Once the silicone cures, you remove the master, leaving a precise cavity for your parts.

The main components involved in this process include:

Master mold

Silicone mold

Casting box

Liquid silicone

You produce parts by pouring resin into the silicone mold under vacuum. This step removes air bubbles and ensures a flawless finish. The process delivers parts that closely match the final product, making it ideal for testing and validation.

You benefit from vacuum casting when you need flexibility, speed, and quality in your product development. Manufacturers often select this process for several reasons:

Cost-effectiveness: You avoid high upfront costs, making it suitable for small to medium runs.

High-quality results: You achieve excellent surface finishes and tight tolerances, which are essential for prototypes.

Material versatility: You can choose from a wide range of resins to mimic different properties.

Speed: You accelerate your rapid prototyping cycle with short turnaround times.

Customization and complexity: You produce intricate shapes and fine details with ease.

Tip: Vacuum casting stands out from other methods because it uses a vacuum to eliminate air bubbles, resulting in higher quality parts. For example, centrifugal casting cannot match this level of detail or consistency, especially for complex designs.

| Aspect | Vacuum Casting | Centrifugal Casting |

|---|---|---|

| Process | Uses vacuum to remove bubbles | Relies on rotation, no vacuum |

| Design Capability | Handles complex and simple shapes | Less effective for complex parts |

| Quality | Minimal bubbles, high precision | Risk of porosity in detailed components |

| Speed | Slightly slower due to vacuum step | Faster for large batches |

| Equipment | Requires vacuum chamber | Simpler setup |

You find vacuum casting widely used in industries such as automotive, medical devices, aerospace, and consumer goods. This process gives you the confidence to move from concept to production quickly and efficiently.

You begin the vacuum casting process by creating a master model. This model serves as the template for every part you produce. You can choose from several materials for your master, each offering unique benefits. Wax allows you to shape fine details easily. Plastic gives you durability and versatility. Metal provides strength and works well for high-quality models.

| Material Type | Description |

|---|---|

| Wax | Used for its ease of shaping and detail retention. |

| Plastic | Commonly used for its durability and versatility. |

| Metal | Chosen for its strength and suitability for high-quality models. |

You ensure the master model has a flawless surface. Any imperfection on the master will transfer to every prototype you cast.

Next, you create the silicone mold by encasing the master model in liquid silicone. The silicone cures around the master, capturing every detail. You then split the mould to remove the master, leaving a precise cavity. The silicone mold can reproduce complex shapes and fine textures.

The hardness of the silicone affects the accuracy of your mould. Softer silicone may cause greater deviations, so you should experiment to find the right balance.

| Silicone Hardness | Impact on Accuracy | Recommendation |

|---|---|---|

| Softer | Greater deviations | Experiment with slightly softer silicone for balance |

You can use each silicone mold for multiple cycles, making the vacuum casting process efficient for low-volume production.

You prepare the resin and pour it into the silicone mold. The vacuum casting process uses a vacuum chamber to remove air bubbles from the resin. This step ensures that the resin fills every part of the mould, even in complex areas. You then cure the resin, either at room temperature or with gentle heat, to solidify the part. This process produces parts that closely match your original prototype.

After curing, you remove the part from the silicone mold. You perform several finishing techniques to achieve a production-quality appearance.

| Finishing Technique | Description |

|---|---|

| Trimming and Polishing | Excess material, like flash or sprues, is trimmed away. Polishing may be done to improve the surface finish. |

| Painting or Coating | Additional finishing steps, like painting or applying protective coatings, are performed to achieve the desired look and durability. |

| Quality Checks | Each part is inspected for defects, including air pockets, warping, or incomplete filling. High-precision tools are often used to verify dimensions and tolerances. |

You inspect each part for defects and verify dimensions. You can apply paint or coatings to match the final product's appearance. This final step ensures your vacuum casting process delivers parts ready for presentation or functional testing.

You achieve high-quality parts in vacuum casting by focusing on essential design elements. Proper design ensures your functional prototypes meet both visual and mechanical requirements. Start by maintaining consistent wall thickness. Thin walls below 0.75 mm can lead to weak spots, while overly thick sections may cause warping. Bosses and ribs add strength but require careful sizing. Draft angles help you remove parts from the silicone mold without damage.

Here is a quick reference for critical design parameters:

| Design Aspect | Recommendation |

|---|---|

| Wall Thickness | At least 0.75-1.0 mm |

| Bosses | Minimum height and diameter of 1.0 mm |

| Boss Wall Thickness | No more than 60% of wall thickness |

| Rib Thickness | No more than 60% of wall thickness |

| Rib Height | No more than 3x rib thickness |

| Draft Angles | At least 1 to 2 degrees |

Tip: Always design with porosity and shrinkage in mind. Use a vacuum chamber to remove trapped air and allow for slight shrinkage during the process.

You control the surface finish and mechanical properties of your functional prototypes by selecting the right materials. Smooth surfaces work best for visible parts, while textured finishes can hide minor imperfections. Material choice also affects transparency, color, glossiness, and strength. For example, PMMA-like resins give you clear parts, while rubber-like materials offer flexibility.

| Property Type | Description |

|---|---|

| Surface Finish | Smooth for aesthetics, textured to mask flaws |

| Transparency | Choose clear or opaque based on application |

| Color Options | Match brand or product requirements |

| Glossiness | Select for matte or glossy appearance |

| Strength | Ensure load capacity for functional prototypes |

| Flexibility | Needed for parts that bend or flex |

| Impact Resistance | Important for shock-absorbing components |

| Hardness | Determines resistance to surface deformation |

You ensure your vacuum casting prototypes meet both visual and functional needs by matching material properties to your application.

You avoid costly errors by recognizing common design pitfalls in high precision vacuum casting. Inappropriate material selection leads to poor quality and higher costs. Unreasonable mold design causes uneven thickness and weak areas. Incorrect forming temperature can result in sagging or incomplete parts. Improper forming speed or cooling time introduces warping and dimensional instability. Neglecting post-processing leaves sharp edges and an unfinished look.

| Common Mistake | Impact on Final Part Quality |

|---|---|

| Inappropriate Material Selection | Poor quality, higher costs, unmet requirements |

| Unreasonable Mold Design | Uneven thickness, weak spots, aesthetic defects |

| Incorrect Forming Temperature Setting | Sagging, incomplete forming, poor definition |

| Improper Forming Speed/Cooling Time | Stresses, warping, dimensional instability |

| Neglecting the Post-Processing Phase | Poor fitment, sharp edges, unfinished appearance |

Note: You improve the quality of your functional prototypes by reviewing your design at every stage and following best practices for rapid prototyping.

You find vacuum casting applications essential in the automotive sector. This process lets you create high-quality vacuum casting parts for both prototypes and functional components. You can quickly develop and test interior trims, dashboard parts, and under-the-hood components. The ability to produce dashboard fascias, instrument clusters, center console housings, and gear shift surrounds allows you to validate designs before mass production. You achieve high dimensional accuracy and surface finish, which is crucial for evaluating design modifications and material properties. This approach supports rapid prototyping and helps you bring new vehicles to market faster.

Interior trims

Dashboard fascias and instrument clusters

Center console housings and storage compartments

Door handle bezels and window switch panels

Gear shift surrounds and climate control interfaces

Speaker grilles and ventilation outlets

Under-the-hood components

Vacuum casting applications in consumer goods manufacturing help you accelerate product development. You can create functional prototypes and small-batch plastic parts that bridge the gap between prototyping and large-scale production. The process leverages silicone molding and urethane casting, making it adaptable for various product designs.

| Advantage | Description |

|---|---|

| Remarkable Precision | Produces highly accurate and detailed prototypes with excellent dimensional stability. |

| Diverse Material Options | Offers a variety of materials for different applications, enhancing design versatility. |

| Cost-effective Production | Reduces costs compared to traditional manufacturing methods, making it ideal for small batches. |

| Rapid Turnaround Times | Enables quick iterations and functional testing, speeding up the development process. |

| Design Versatility | Allows for complex geometries and intricate textures, accommodating various design needs. |

You benefit from rapid prototyping and the ability to test vacuum casting parts quickly, ensuring your products reach the market efficiently.

You rely on vacuum casting for aerospace and medical device prototypes because it delivers high production quality and quick turnaround times. You can create complex geometries without design constraints, using both rigid and flexible materials. The flexibility of silicone molds means you do not need draft angles, which simplifies the design process.

Quick turnaround time for prototypes

Ability to create complex geometries

Flexibility in material options, including rigid and flexible materials

No need for draft angles due to silicone mold flexibility

You find this process ideal for making functional prototypes and medical device prototypes quickly and cost-effectively. You can iterate designs rapidly, test and refine them, and produce low-volume batches without high upfront costs. Over molded parts, combining rigid and flexible materials, are possible. Biocompatible polyurethane resins make vacuum casting suitable for medical applications, including custom medical equipment and testing devices.

You use vacuum casting to produce industrial equipment components that demand superior material properties and precision. This process reduces porosity and enhances mechanical properties, which is crucial for superalloys and high-performance parts. You can achieve intricate designs and tight tolerances, ensuring your vacuum casting parts meet strict industry standards.

Superior material properties with reduced porosity

Complex geometries and tight tolerances

Excellent surface finish, minimizing additional finishing

Material efficiency by controlling molten material flow

You gain reliable, high-quality components for industrial machinery, supporting a wide range of applications of vacuum casting in demanding environments.

You gain significant cost-effectiveness when you choose vacuum casting for low-volume production. The process uses silicone molds, which cost much less than steel tooling required for injection molding. You avoid high upfront investments and pay only for what you need. For small batches, vacuum casting can save you 30–60% compared to injection molding. CNC machining also carries higher costs for complex shapes and generates more material waste.

You reduce tooling expenses with silicone molds.

You avoid large investments for small runs.

You benefit from cost-effectiveness for prototypes and pilot batches.

| Method | Typical Tooling Cost | Best for Volume | Cost-Effectiveness |

|---|---|---|---|

| Vacuum Casting | Low | 1–50 parts | High |

| Injection Molding | High | 10,000+ parts | Low for small runs |

| CNC Machining | None | 1–10 parts | Moderate |

Tip: Vacuum casting gives you the flexibility to test designs without committing to expensive tooling.

You experience a quick turnaround with vacuum casting. The process typically delivers parts in 1–2 weeks, which helps you accelerate your development cycle. Injection molding requires longer lead times for tooling, but once molds are ready, production speeds up. CNC machining can produce parts quickly, but costs rise with complexity.

Vacuum casting offers a turnaround of 1–2 weeks.

Injection molding needs more time for mold creation.

CNC machining is fast for simple parts.

You can move from design to prototype in days, not months, when you use vacuum casting.

You unlock greater design flexibility with vacuum casting. The process adapts to intricate geometries, allowing you to create ribs, undercuts, and embossed logos with ease. You can make design changes quickly and cost-effectively because silicone molds are easy to modify or replace. Vacuum casting excels at producing prototypes and small production runs with excellent surface finish and detail.

You create complex shapes without limitations.

You adjust designs affordably for each iteration.

You achieve high-quality finishes for functional and visual testing.

Vacuum casting supports innovation by letting you experiment with new ideas and refine your products before scaling up production.

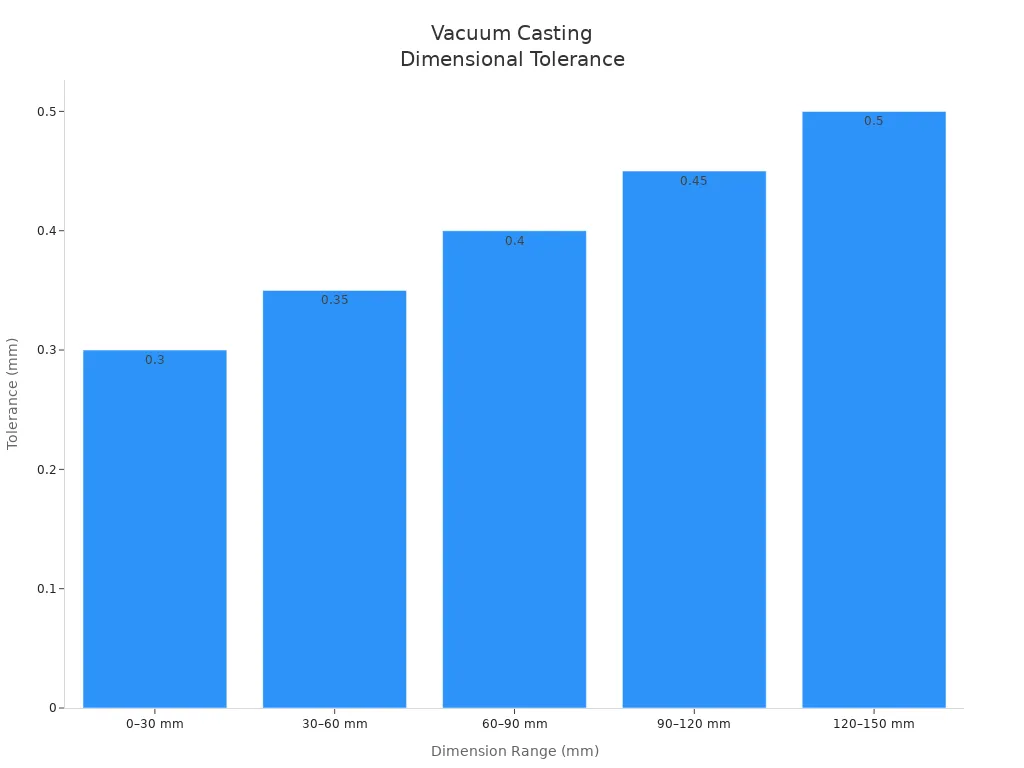

You expect high precision from the vacuum casting process, especially when you need reliable prototypes or small-batch parts. Dimensional accuracy is a top priority. Most projects achieve tolerances that meet or exceed industry standards. For example, you can maintain tight tolerances across a range of part sizes:

| Dimension (mm) | Tolerance (mm) |

|---|---|

| 0–30 | +/- 0.3 |

| 30–60 | +/- 0.35 |

| 60–90 | +/- 0.4 |

| 90–120 | +/- 0.45 |

| 120–150 | +/- 0.5 |

You can see how tolerance changes with part size in the chart below:

Shrinkage rates in vacuum casting remain low, which helps you maintain dimensional accuracy and fit. Typical shrinkage falls between 0.15% and 0.30%. This low shrinkage means your parts will fit together well during assembly and testing.

| Shrinkage Rate (%) | Description |

|---|---|

| 0.15% to 0.30% | Typical shrinkage rates in vacuum casting, which are lower than injection molding but can still affect assembly. |

Note: Always account for shrinkage in your design to ensure the final part meets your dimensional requirements.

You select materials based on the performance you need from your parts. Vacuum casting supports a wide range of resins, each with unique properties. You can choose materials that offer high elasticity, rigidity, or temperature resistance. For example, you might use polycarbonate or PMMA for parts that need to withstand higher temperatures or require shock resistance. Rubber and polypropylene provide flexibility and impact absorption. Glass-filled nylon and ABS deliver strength and dimensional stability.

| Material Type | Properties |

|---|---|

| Rubber | High elasticity |

| ABS | High rigidity and strength |

| Polypropylene and HDPR | High elasticity |

| Polyamide and glass-filled nylon | High rigidity |

| Polycarbonate and PMMA | Shock resistant, translucent, high temperature resistant |

You should always match your material choice to the demands of your application. This approach ensures you achieve the right balance of dimensional accuracy, precision, and durability in every part you produce.

You can scale your vacuum casting projects efficiently by following proven best practices. When you plan for high-volume pilots, focus on optimizing each step to maintain quality and control costs. Vacuum casting works best for low to medium production volumes, usually up to a few hundred parts. You achieve excellent results when you use this process for prototyping and small-batch production of complex components.

| Best Practice | Description |

|---|---|

| Production Volume | Use vacuum casting for up to a few hundred parts to maximize efficiency. |

| Prototyping | Leverage the process for detailed prototypes and small batches. |

| Comparison | Switch to injection molding for higher volumes to reduce per-part cost. |

You produce high-quality prototypes with vacuum casting.

You manage low to medium volume runs with consistent results.

You improve efficiency and cost-effectiveness by understanding each process step.

Tip: Plan your production schedule carefully. You extend mold life and reduce downtime by rotating molds and monitoring wear.

You enhance the quality of your vacuum casting projects by using iterative design and feedback loops. This approach helps you refine prototypes and meet your objectives faster. Start by defining clear goals for your prototype, including performance and functionality. Build your initial prototype using rapid prototyping methods. Test the part and gather feedback from users and stakeholders. Analyze the feedback to identify areas for improvement. Repeat the cycle until your prototype meets all requirements.

Define objectives and criteria for your prototype.

Design and build the first version using rapid prototyping.

Test and evaluate the prototype with stakeholders.

Analyze feedback and refine the design.

Repeat the cycle until you reach your goals.

Note: You accelerate development and improve part quality by embracing continuous improvement and feedback.

You gain significant advantages with vacuum casting across industries.

Automotive and aerospace sectors benefit from rapid prototyping and cost savings.

Medical and healthcare fields rely on precise, customized components.

Consumer goods and electronics manufacturers test product designs efficiently.

Industrial equipment producers create durable, small-batch parts.

You see innovations such as automation, AI-driven optimization, and multi-material casting. The industry moves toward sustainable practices and faster production cycles.

| Innovation Type | Description |

|---|---|

| Automation | Smart systems improve precision and reduce cycle times. |

| AI Integration | AI enhances consistency and minimizes defects. |

| Multi-Material Casting | Simultaneous casting increases versatility. |

You select from a wide range of polyurethane resins, including ABS-like, rubber-like, and transparent grades. These materials allow you to match the mechanical and visual properties of your final production parts.

You typically create 10 to 25 parts from a single silicone mold. Mold life depends on part complexity, material choice, and the level of detail required for your prototypes.

You achieve lower tooling costs and faster turnaround with vacuum casting vs injection molding. This method suits small batches and prototypes, while injection molding works best for high-volume manufacturing.

You produce intricate details and smooth surfaces with vacuum casting vs 3d printing. Silicone molds capture fine features, and the process eliminates layer lines, resulting in parts that closely resemble final products.

You find vacuum casting widely used in automotive, aerospace, medical devices, consumer electronics, and industrial equipment. These sectors rely on rapid prototyping and small-batch production for testing and validation.

Tip: Always consult with your manufacturing partner to select the best process for your project needs.