Email: admin@yeeshine-tech.com WhatsApp: +86-13712868936

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-05-13 Origin: Site

Plastic injection molding has long been the go-to manufacturing method for producing high-precision, repeatable plastic parts across various industries. Among the many advanced techniques within this process, partial injection molding stands out as a flexible solution that enables creative part designs, multi-functional components, and lightweight structures.

Partial injection molding refers to a specialized injection molding technique where only a portion of the mold cavity is filled with molten plastic rather than filling the entire cavity in a single shot. It differs from conventional full-cavity molding by allowing more control over material flow, injection timing, and the layering or combination of different materials and colors.

This technique is used to produce parts with varying thicknesses, multiple materials (soft and hard plastics), or different colors within the same part. Rather than injecting all the material at once, the process may involve sequential injection, stage-by-stage filling, or partial cavity engagement, depending on the application.

Partial injection molding is often supported by 2K molds (two-component molds) or multi-shot molding machines, especially when combining rigid and flexible plastic materials in one product.

Partial injection molding opens new doors for product design and functional integration. Here are some key scenarios where this method is highly effective:

In sectors such as automotive and electronics, reducing weight is essential for performance and energy efficiency. Partial injection molding allows engineers to create parts with hollow sections or foam-like structures while maintaining the necessary mechanical strength. By injecting less material in select areas, manufacturers can decrease part weight without sacrificing integrity.

Many consumer goods and electronics use a combination of two materials—such as a rigid base with a soft-touch grip. With partial injection molding, one material can be injected into part of the cavity, and a second material follows in a subsequent stage to complete the design. This process, called 2K or overmolding, helps create multi-functional parts with better ergonomics and aesthetics.

Partial injection molding is commonly used in electronic part encapsulation, where circuits or sensors need to be partially covered by protective plastic without affecting other parts. It’s also used to create durable keypads, grips, or handles, where the soft outer material only covers specific areas.

This technique is helpful when combining plastic with non-plastic components. For example, metal inserts like nuts, rods, or magnets can be placed into the mold before partial plastic injection, allowing the plastic to surround or anchor them in specific areas. This approach reduces assembly time and increases product durability.

Products like toothbrushes, automotive knobs, and consumer device buttons often consist of layered materials with different colors or hardness levels. Partial injection molding makes it possible to create these complex structures in a single mold cycle, reducing secondary processing.

The partial injection molding process involves sophisticated coordination between mold design, machine control, and material selection. Below is a breakdown of how it works in practice:

The most basic form of partial injection molding is simply controlling the amount of plastic injected. Instead of filling the entire mold cavity, the injection unit is programmed to stop at a precise volume. This can be used to:

Prevent over-packing

Create cavities or hollow spaces

Allow for post-injection processes such as foaming or insert loading

In more advanced applications, the process is divided into multiple stages. For example:

Stage 1: Inject the first material into a portion of the mold cavity

Stage 2: Once cooled or partially set, inject the second material or color into the remaining space

This is often achieved using multi-barrel injection molding machines or machines with rotating mold bases for 2K injection molding. The mold is designed to redirect the second material into specific areas without disturbing the first.

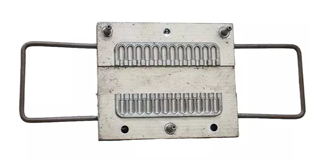

The plastic injection mold plays a crucial role in partial injection molding. It must be engineered with:

Multiple gates for independent material flow

Rotational or sliding mechanisms for changing cavity positions between injections

Insulation and venting systems to accommodate different resin types

High-quality plastic injection molds allow materials to bond at a molecular level while maintaining tight dimensional tolerances.

To ensure perfect synchronization between material changes, gate control, and pressure adjustment, the injection molding machine must offer:

High-resolution servo motors

Closed-loop feedback systems

Accurate melt temperature and pressure sensors

Multi-zone heating systems

YEESHINE’s advanced machines integrate these technologies for perfect execution of partial injection cycles.

At YEESHINE TECHNOLOGY CO., we specialize in high-performance plastic injection molding machines and custom mold solutions tailored to partial injection needs. Our systems support:

2K injection molding (two-component molding)

Multi-color and multi-material molding

Overmolding and insert molding applications

Complex part geometries and fine detail reproduction

Our dual-barrel systems allow precise control over each material’s temperature, pressure, and injection timing. Whether you’re combining soft-touch elastomers with rigid polymers or injecting two colors into a single mold, our equipment ensures seamless integration.

YEESHINE’s machines are compatible with custom plastic injection molds, including rotating, sliding, and indexing molds designed for sequential injection or encapsulation.

With PLC-based closed-loop control, our machines monitor and adjust parameters in real-time, ensuring flawless transition between injection stages with minimal operator input.

Our engineering team assists in mold design, material selection, and process optimization to ensure your partial injection molding project is successful from start to finish.

Partial injection molding offers a wide array of benefits across design, production, and cost:

Greater Design Flexibility: Create complex or multi-functional parts with multiple materials or colors

Improved Aesthetics: Seamless surface integration with no need for secondary painting or coating

Lightweighting: Reduce plastic usage and part weight without compromising strength

Lower Assembly Costs: Combine multiple functions or components into a single molding cycle

Enhanced Durability: Superior bonding between layers or materials increases part longevity

These benefits make partial injection molding a valuable asset for competitive product design in modern manufacturing.

Partial injection molding represents a powerful evolution in plastic manufacturing. By enabling controlled, sequential, or multi-material injection within a single molding cycle, it expands what’s possible in product design and functional integration.

Whether you’re aiming to reduce weight, enhance visual appeal, or build parts with varying material characteristics, partial injection molding offers a flexible, efficient solution. At the heart of this process are precision machines and expertly designed plastic injection molds—both of which must work in harmony to achieve success.

YEESHINE TECHNOLOGY CO. is a trusted partner in delivering advanced injection molding machines and turnkey solutions for partial injection molding. With dual-color molding capabilities, intelligent controls, and custom mold engineering, we empower manufacturers to create the next generation of innovative plastic components.

To explore how partial injection molding can transform your product line, visit www.yeeshine-tech.com or contact us for expert consultation and tailored equipment solutions.