Email: admin@yeeshine-tech.com WhatsApp: +86-13712868936

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-06-30 Origin: Site

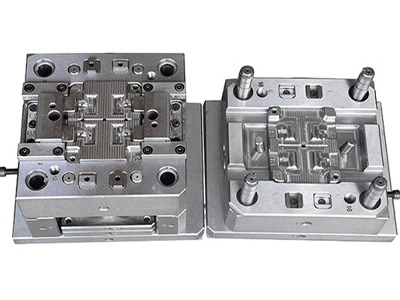

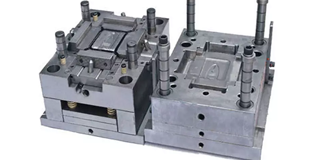

The automotive industry has long been a leader in technological innovation, with businesses constantly pushing the boundaries of design, precision, and production efficiency. One of the most critical stages of automotive development is the prototyping and small-scale production of parts. Traditionally, this process has involved expensive, high-volume equipment that is not always accessible for startups and small manufacturers. However, the advent of desktop injection molding machines is revolutionizing this process, offering a more affordable and efficient way for startups to create high-quality prototypes and low-volume production parts.

Desktop injection molding machines are compact, affordable, and highly versatile machines that allow small businesses to manufacture complex and high-precision components in-house. These machines are designed to provide the speed and flexibility necessary for rapid prototyping, small-batch production, and iterative design improvements. For automotive startups, this means reducing costs, speeding up production times, and enabling the quick testing and modification of components—ultimately helping them bring innovative ideas to market faster than ever before.

In the automotive sector, innovation is paramount. Whether it's designing the latest electric vehicle, creating a new engine component, or improving the safety features of a car, prototyping plays a critical role in the development process. Traditionally, automotive companies needed access to large, expensive industrial machines to produce parts. For startups and smaller manufacturers, this meant significant upfront costs, long lead times, and limited flexibility.

However, desktop injection molding machines have changed the game for smaller businesses. These machines, typically used in low-volume production and rapid prototyping, are making it easier and more cost-effective for startups to produce high-quality automotive parts. Whether it's creating custom components for a prototype or producing small batches of parts for testing and validation, desktop injection molding machines allow automotive startups to do all of this and more without the need for extensive investment in industrial machinery.

With desktop injection molding machines, businesses can achieve the precision and speed required for automotive parts manufacturing, while also keeping costs down. This technology empowers startups to iterate quickly, test their designs, and refine components without the need to commit to large-scale production. Moreover, it allows companies to bring their products to market faster, which is crucial in an industry where time-to-market is a key competitive advantage.

One of the key benefits of desktop injection molding machines is their ability to produce highly customized components for automotive prototypes. The automotive industry is known for its need for precision and high performance, and any deviation from the required specifications can lead to costly design errors. Desktop injection molding machines enable businesses to create prototype parts that meet exacting standards of accuracy and functionality, allowing for faster iterations and more effective testing.

With desktop injection molding machines, automotive startups can produce a wide range of parts, from small interior components to larger exterior elements, all with the fine detail required for automotive manufacturing. Components like brackets, gears, connectors, switches, and casing elements—common in automotive applications—can all be produced using desktop injection molding technology. These machines can handle various materials, such as engineering-grade plastics and specialized compounds, ensuring that the prototypes are both functional and durable.

The flexibility of desktop injection molding machines means that automotive startups are no longer restricted to rigid and costly manufacturing processes. These machines offer the freedom to experiment with different materials, designs, and components without the need for expensive, high-volume equipment. For example, designers can quickly test different materials for durability and performance under real-world conditions, and if a design flaw is discovered, the machine allows for rapid redesign and re-testing.

In the fast-paced world of automotive innovation, the ability to quickly iterate on designs is essential. Traditional manufacturing methods can take weeks or even months to produce prototypes, while larger machines require significant setup times and cost per mold. Desktop injection molding machines eliminate these barriers, offering rapid turnaround times that help automotive startups reduce design cycle times and improve the efficiency of product development.

By allowing for quick design iterations, desktop injection molding machines enable automotive startups to refine their designs and optimize components at every stage of development. Once a prototype is produced, it can be tested, evaluated, and modified, and a new version can be produced within hours or days. This reduces the risk of costly mistakes that might arise from waiting for months to receive feedback from traditional manufacturing methods.

Additionally, the compact size and flexibility of desktop injection molding machines allow for the easy testing of multiple designs in parallel. If an automotive startup is working on several different components for a vehicle, the ability to prototype and test each one independently and concurrently can save substantial time and resources. This rapid feedback loop fosters a more efficient design process and ensures that each component meets the necessary standards before it enters mass production.

Startups in the automotive industry often face significant challenges when it comes to low-volume production. Traditional injection molding machines are expensive to set up and require substantial upfront investment, making them impractical for small manufacturers or prototype-based projects. Additionally, these machines are often optimized for large-scale production runs, making them inefficient for low-volume manufacturing.

Desktop injection molding machines are ideal for low-volume production, offering a cost-effective solution for startups and small manufacturers. These machines do not require the expensive molds and complex setup that traditional industrial machines do, making them much more accessible for low-volume production runs. This allows automotive startups to produce small batches of components for testing, limited production, or even short-run orders without breaking the bank.

The affordability of desktop injection molding machines means that startups can allocate their resources more efficiently. With fewer capital expenses required for manufacturing setup, startups can invest more in product development, marketing, or other essential areas of their business. Furthermore, the ability to produce small quantities of parts without committing to large production runs allows startups to test the market, gather feedback, and make adjustments to their designs without the risk of overproducing parts that may not be needed.

Moreover, desktop injection molding machines also offer reduced material waste. Since startups can produce exactly the number of components they need, they avoid the common issue of excess inventory or the need for large quantities of raw materials. This efficiency contributes to cost savings while minimizing environmental impact, making it a smart choice for eco-conscious automotive startups.

Desktop injection molding machines are rapidly becoming an essential tool for automotive startups looking to streamline their prototyping and production processes. These machines offer a cost-effective, flexible, and efficient way for businesses to create high-quality automotive components, test designs, and refine prototypes before committing to large-scale production. The precision, speed, and flexibility offered by desktop injection molding machines enable startups to reduce lead times, iterate quickly, and bring innovative products to market faster.

By embracing this technology, automotive startups can gain a competitive edge in an industry where speed, precision, and cost control are key. Desktop injection molding machines allow for more efficient prototyping, low-volume production, and the ability to make real-time design adjustments without the need for costly and time-consuming processes.

For automotive startups seeking to enhance their prototyping and production capabilities, YEESHINE TECHNOLOGY CO. offers cutting-edge desktop injection molding solutions that cater to the needs of small manufacturers and design engineers. To explore how these machines can benefit your business or to discuss customized solutions, contact YEESHINE TECHNOLOGY CO. today. Their team of experts is ready to assist you in achieving your production goals while keeping costs low and efficiency high.