Email: admin@yeeshine-tech.com WhatsApp: +86-13712868936

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-05-07 Origin: Site

Polyvinyl chloride, commonly known as PVC, is one of the most widely used plastic materials globally, especially in plumbing, construction, and electrical conduit industries. PVC fittings, such as elbows, tees, couplings, and adapters, are essential components in piping systems, connecting pipes and directing flow.

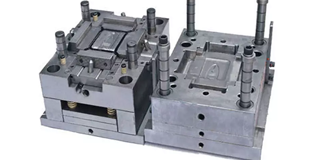

Injection molding of PVC fittings requires careful consideration due to the material’s unique properties. PVC is a thermoplastic polymer with excellent chemical resistance, mechanical strength, and durability, but it also poses specific challenges during molding. The process involves melting PVC pellets and injecting the molten plastic into a mold cavity shaped like the fitting.

Producing high-quality PVC fittings through injection molding demands the right type of injection molding machine equipped with specific features to handle PVC’s characteristics. Understanding these machine requirements is crucial for manufacturers aiming to deliver durable, defect-free PVC fittings efficiently.

PVC has some distinctive physical and chemical traits that affect how it behaves during injection molding. To successfully mold PVC fittings, the injection molding machine must have specific capabilities, especially regarding corrosion resistance, temperature control, and venting.

PVC contains chlorine, which can release corrosive hydrogen chloride gas when heated. This corrosive gas can damage the injection molding machine’s barrel, screw, and other components if they are not made from corrosion-resistant materials.

Material of Barrel and Screw: For PVC injection molding, machines with barrels and screws made of stainless steel or specially coated steel are preferred. These materials resist corrosion and extend the lifespan of machine parts.

Protective Coatings: Some machines have tungsten carbide or chrome plating on screws and barrels to withstand PVC’s corrosive effects.

Regular Maintenance: Due to the corrosive nature of PVC, machines used for PVC must be cleaned and maintained frequently to avoid damage and ensure product quality.

Temperature control is critical in PVC injection molding. PVC is sensitive to overheating, which can cause degradation, discoloration, and loss of mechanical properties.

Precise Temperature Regulation: Injection molding machines for PVC need advanced temperature control systems that maintain barrel and mold temperatures within a narrow range, usually between 160°C and 210°C.

Cooling System Efficiency: Efficient cooling systems prevent the mold and barrel from overheating during the injection cycle, ensuring consistent quality.

Temperature Zoning: Multiple temperature zones along the barrel allow gradual heating of PVC pellets, reducing thermal shock and preventing premature degradation.

During the melting process, trapped gases and volatiles need to be vented properly to avoid defects like bubbles, voids, or burn marks.

Machine Venting: PVC injection molding machines must have excellent venting systems to remove hydrogen chloride gas and other volatiles produced during heating.

Mold Venting: In addition to machine venting, molds must have well-designed venting channels to allow trapped air and gases to escape during injection.

Besides corrosion resistance, temperature control, and venting, several critical machine configurations influence the quality and efficiency of PVC fitting production. These configurations ensure the machine can handle the specific requirements of PVC injection molding.

The clamping force of an injection molding machine is the pressure used to keep the mold closed during injection. PVC fittings can vary in size and thickness, affecting the required clamping force.

Correct Clamping Force: The machine must have enough clamping force to prevent mold separation and flashing (excess plastic leakage) during injection. For small to medium PVC fittings, machines with clamping forces ranging from 100 to 300 tons are common.

Adjustability: The ability to adjust clamping force according to part size and mold complexity is important for optimizing cycle times and reducing wear on molds.

Balanced Force Distribution: Machines with even clamping pressure ensure uniform cavity filling and reduce defects such as warping or incomplete filling.

The injection screw’s design is vital for melting, mixing, and injecting PVC material efficiently.

Screw Length-to-Diameter Ratio (L/D): A longer screw (L/D ratio of 20:1 to 24:1) provides better plasticizing and mixing of PVC pellets, ensuring uniform melt temperature and viscosity.

Screw Profile: Screws designed with specific compression and metering zones for PVC improve melting efficiency without overheating.

Corrosion-Resistant Screw Materials: As mentioned, screws must be corrosion-resistant and wear-resistant to withstand PVC processing.

Barrier Screws: Some machines use barrier screws to separate molten PVC from solid pellets, reducing the risk of degradation.

Cooling is essential to solidify the PVC fitting quickly and maintain dimensional accuracy.

Water Cooling Channels: Molds used for PVC fittings must have well-designed water cooling channels to rapidly remove heat after injection.

Chillers and Mold Temperature Controllers: Injection molding machines equipped with chillers maintain consistent mold temperature, improving cycle time and part quality.

Balanced Cooling: Uniform cooling prevents warpage, shrinkage, and internal stresses in PVC fittings.

PVC fittings often require precise control of injection speed and pressure to avoid defects such as short shots or flash.

Variable Injection Speed: Machines with adjustable injection speed can accommodate complex PVC fittings with thin walls or detailed features.

Pressure Sensors: Real-time pressure monitoring helps maintain consistent injection parameters and detect molding anomalies early.

Multi-Stage Injection: Some machines offer multi-stage injection control to optimize filling and packing phases.

To further improve PVC fitting production, some injection molding machines come with special features tailored for PVC processing.

PVC pellets often require drying before injection molding to remove moisture and prevent defects. Machines integrated with hopper loaders and drying systems ensure continuous supply of dry resin.

Automated systems such as robotic arms for part removal, conveyor belts, and vision inspection systems improve efficiency and quality control in PVC fitting production.

Advanced injection molding machines use servo motors and energy-saving hydraulic systems, reducing operating costs while maintaining precise control.

Several manufacturers specialize in injection molding machines suitable for PVC fitting production. These machines share the key features outlined above and are designed to meet the demands of PVC processing.

Traditional hydraulic machines are widely used for PVC injection molding due to their high clamping force and stable pressure control. Modern hydraulic machines often incorporate energy-saving features.

Electric machines provide high precision, faster cycle times, and cleaner operation. Their superior temperature control and injection accuracy make them well-suited for complex PVC fittings requiring tight tolerances.

Hybrid machines combine hydraulic power with electric servo motors to balance energy efficiency, speed, and precision. They are increasingly popular for PVC fitting production.

Match Clamping Force to Part Size: Avoid underpowered or overpowered machines; select clamping force based on the size and complexity of the PVC fitting.

Ensure Corrosion Resistance: Choose machines with corrosion-resistant barrels and screws to prevent premature wear.

Prioritize Temperature Control: Look for machines with advanced multi-zone heaters and mold temperature controllers.

Check Venting Capabilities: Ensure both the machine and molds provide adequate venting to prevent defects.

Consider Automation Needs: Factor in whether robotic part handling or drying integration is required.

Evaluate Energy Efficiency: Modern servo or hybrid machines can reduce long-term costs.

Producing high-quality PVC fittings through plastic injection molding requires a specialized machine with corrosion-resistant components, precise temperature control, and effective venting. Key features like optimized screw design, proper clamping force, and efficient cooling systems are essential to ensure consistent, defect-free results.

If you’re looking to invest in reliable equipment for PVC fitting production, YEESHINE TECHNOLOGY CO. offers advanced injection molding machines specifically engineered for PVC applications. With years of expertise and a strong focus on precision and efficiency, YEESHINE can help you achieve superior product quality and production performance.

To learn more or request a customized solution, visit YEESHINE’s website or contact their team today.