Email: admin@yeeshine-tech.com WhatsApp: +86-13712868936

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-08-20 Origin: Site

Ever wonder how metal parts are shaped so precisely and quickly? Stamping die design is the secret behind modern manufacturing speed and accuracy.

This guide is for engineers, toolmakers, and production planners seeking better results. You'll learn die types, design steps, materials, and smart tooling techniques.

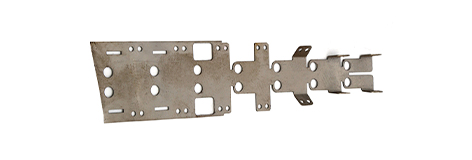

A stamping die is a custom-made tool used to shape or cut metal sheets. It's placed inside a press machine and applies force to form parts. Depending on how it's designed, it can cut, bend, draw, or punch metal into many shapes. These dies are essential in creating consistent, high-quality parts like brackets, clips, covers, and connectors. They’re often used in industries like automotive, electronics, appliances, and aerospace. The press and die must match perfectly so each part is made to exact specifications. Without a proper die, even simple metal parts would take too long to make or wouldn’t be uniform.

Dies play a huge role in automated manufacturing. They help reduce labor, speed up production, and lower costs. Since dies are used in machines that operate at high speed, they must be accurate and durable. A well-designed die supports automatic feeding systems, so parts can be made continuously without stopping. In high-volume lines, progressive dies allow multiple operations in one stroke. That’s why most modern factories rely on them to meet tight deadlines and quality goals. If the die fails, production stops. So keeping it in top shape is just as important as designing it right.

Here’s a short list of words you’ll often see in die design:

| Term | Meaning |

|---|---|

| Die Shoe | The base that supports the die and keeps it steady |

| Punch | A part that pushes into the metal to cut or shape it |

| Die Plate | The part that holds the cutting edges or forming surfaces |

| Guide Pin | A pin that keeps the upper and lower dies aligned during pressing |

| Bushing | A smooth tube that the guide pin moves through |

| Strip Layout | The plan for how parts will be spaced and cut from the metal strip |

| Press Tonnage | The amount of force the press machine can apply |

| Shut Height | The distance between the press ram and bed when fully closed |

| Blanking | Cutting out a flat shape from sheet metal |

| Piercing | Making holes or openings in the sheet |

These terms are the foundation for understanding how dies work in production.

A stamping die set is made of several important parts that work together to shape metal. The die shoes are the base plates. They hold everything in place and give the whole setup strength. Then there are die plates, which include cutting and forming features. They make contact with the metal during each press cycle. Guide pins and bushings are added to keep the upper and lower parts aligned as the die opens and closes. If they’re not aligned, the tool could break or produce bad parts. Strippers help remove the metal from the punch after cutting or forming. Without them, the material might stick or get damaged. Each part has to be designed carefully so it fits the overall die structure and press setup.

Choosing the right material is a big deal in die design. Most engineers go with steel because it’s strong, durable, and affordable. But not all steel is the same. Some use low-carbon types because they’re easy to machine. Others pick harder grades for better wear resistance. For lighter dies that need speed, aluminum alloys are used. They cut down weight but still hold shape under pressure. Carbide inserts are added in high-wear zones where the punches hit most often. It’s important to balance strength, machinability, and cost. The material you pick affects how long the die lasts and how often it needs maintenance.

Thickness and size affect how stable the die will be under stress. When the press applies force, the die must hold steady. If the material being stamped is thick or strong, the die plates and shoes must be thicker too. Press capacity also matters. A bigger press with more tonnage puts more load on the die. That’s why engineers check the shut height and stroke range before building. If you’re designing a progressive die with many stations, you’ll need extra support. The layout has to leave enough room for each operation while fitting within the press bed. Get the balance right, and you reduce misalignment, cracks, and downtime.

Simple dies, also called single-hit dies, perform just one action per press stroke. That action might be cutting, bending, or forming. They're easy to build and cheap to maintain, which makes them great for short runs or prototypes. If you only need to punch a hole or trim a part, this is usually the best option. We see these used in repair shops, R&D labs, and low-volume production lines.

Progressive dies are built for speed and precision. They perform multiple steps in one long strip of metal as it feeds through. Each station in the die adds a different operation like bending or punching. By the end, a finished part drops out. These dies work best when you need to make thousands of identical parts fast. Electronics and automotive industries use them daily. But they take longer to design and cost more up front. The payoff is worth it in high-volume runs.

Compound dies do multiple cuts during a single press stroke. Unlike progressive dies, the sheet doesn’t move through different stations. It stays in one spot while the tool punches out several features at once. These dies are perfect for making flat parts like washers or rings. They reduce handling, save time, and keep the cut edges clean. If the part is simple but has more than one cut, this die saves effort.

Combination dies cut and form the material in one motion. They work when a part needs a hole punched and a bend made at the same time. Instead of doing those in two tools, you get it done in one. That means less press time and fewer setups. They’re used a lot in appliance and electronics hardware. But you need good alignment and design to avoid defects, since forming and cutting create very different forces.

Some dies specialize in one task only. A blanking die cuts out the flat shape from a sheet. Piercing dies make holes or slots. Bending dies push the material at a set angle. Forming dies shape the metal into curves or more complex 3D parts. These are the core tools behind nearly every stamped metal part. Each one focuses on just one action, but they’re often combined or sequenced in multi-die setups.

Line dies are used when the job doesn’t need the speed of a progressive die. You place the part manually, or use a feeder, and move it through one station at a time. Each die performs a single function like bending or notching. These are perfect for small batches or larger parts that don’t fit standard progressive tooling. They're common in job shops and custom fabrication where every part is a bit different.

Before jumping into CAD models or tool steel selection, you need to ask one thing first. Can this part actually be stamped? That means checking the shape, size, and material. If it has sharp corners, deep curves, or tight tolerances, it might need forming in stages. Look at wall thickness, grain direction, and what surface finish is required. If it can't be done with standard stamping, you may need to rethink the approach or use secondary processes like machining.

Once the part passes the feasibility check, the next step is picking the best forming method. Should it be blanked, bent, drawn, or maybe pierced? Sometimes it’s a mix. Drawing works for deep cups or housings. Bending is better for angles and brackets. Think about how much the metal will stretch. If you push it too far too fast, it could tear. Plan whether you’ll need intermediate steps like restriking or leveling. That way, the part doesn’t fail halfway through production.

Now it’s time to match the part with the right die style. If the part is simple and made in low volume, a single-hit die might do the trick. If it’s complex and high volume, a progressive die saves time. For tight tolerance cuts, you might need a compound or combination die. It’s not just about geometry. Consider budget, lead time, and press availability too. Every choice affects production speed and final part quality.

This is where the technical work really begins. You’ll design the main frame, working components, and guide systems. Punches, dies, springs, lifters—they all need space and support. Make sure each punch has clearance and backup. Choose tool steel types based on the load each part handles. Carbide is often used for high-wear areas. The goal is to avoid misalignment or deflection. Even a tiny mismatch can ruin thousands of parts.

A good strip layout can cut material costs by a lot. Map how each part will be spaced across the coil. Keep parts close, but leave room for webbing, pilot holes, and burr relief. You don’t want parts jamming the press. Test different layouts to see which gives the most yield from each sheet. Include scrap trimming and carry strip features if needed. Use nesting software if available—it makes a big difference.

Once your layout is ready, shape the die face. This surface controls how the metal flows during pressing. Simulations help you predict wrinkles, springback, or cracks. Use forming limit diagrams and thinning plots to fix trouble zones before building. If the part has complex shapes, you might need to design pre-forms that reshape the material step-by-step. Make sure to adjust draw beads or radius size if the results look uneven or overstretched.

Now it’s time to document everything. Build a full 3D model and extract working drawings. Add shut heights, stroke limits, and material callouts. Check if your design fits the press you plan to use. Follow national or company standards for dimensioning and tolerances. Label part numbers, revisions, and materials clearly. Once approved, the files go to machining and the real die-making begins.

Before cutting steel or ordering tool steel, engineers usually run digital simulations. FEA, or finite element analysis, helps predict how metal will behave under force. It shows where wrinkles, thinning, or splits might happen. We can test different draw bead placements or change radius sizes without wasting material. Another major benefit is blank prediction. It shows the shape of the raw metal before forming. That way, we can avoid extra trimming or wasted material later. Even a small change in the blank shape can save time and reduce scrap in production.

Circle grid analysis is a hands-on way to check how metal stretches. You apply a pattern of circles on a metal sheet, run it through the forming process, then measure how the circles deform. If they stretch into long ovals, it means the area is under tension and could be thinning too much. It’s especially helpful for deep draw or complex forms. Thinning checks help confirm whether the material stays within safe limits. If it's too thin, the part might crack or fail under use. Combined with simulation, this step helps engineers catch problems before mass production begins.

Prototypes take the virtual world into the real one. Even if a design looks perfect in CAD, we still need to test it physically. A prototype tool—sometimes just a single-stage die—is made from softer or less expensive materials. It’s used to stamp a small number of test parts. We check fit, finish, and structural integrity. If the part doesn’t match the print or has visible defects, we can go back and adjust the tooling. This step also lets us test how well the part fits with mating components. In industries like automotive or aerospace, a good prototype stage can prevent months of rework later.

Digital twin technology lets us create a live virtual copy of the die setup. It mirrors the real-world tool, tracks performance, and predicts wear before failure happens. Engineers can test changes in real time without stopping production. If a punch misaligns or a component shows early stress, we’ll catch it early. It saves time, avoids breakdowns, and supports smarter maintenance decisions. This is especially useful in high-volume operations where downtime gets expensive fast.

Some die components are heavier than they need to be. That’s where topology optimization comes in. It uses advanced software to remove material from low-stress areas while keeping strength in key zones. The result is a tool that’s lighter but still rigid. It’s ideal for large dies that need to cycle fast or fit into tight press windows. Lighter tools reduce energy use and make handling safer during setup or maintenance. We often see this paired with 3D printing to create complex shapes that normal machining can’t handle.

3D printing, also called additive manufacturing, gives us total design freedom. We can build inserts, form blocks, or cooling channels layer by layer. For prototype tooling, this method saves time and lets us try new ideas fast. Complex features that would take days to machine can now be printed in hours. It’s not just for plastic either. New machines work with tool steels and hybrid metals, making them suitable for low-run stamping or soft dies in R&D environments.

Laser cutting provides tight tolerances and smooth edges, even in hardened steel. It’s perfect for trimming, blanking profiles, or cutting shims and spacer layers. When we need ultra-fine details or sharp corners, EDM (electrical discharge machining) does the job. It uses electrical sparks to cut through metal without contact. That means no tool deflection or burrs. EDM is often used for punch details, narrow slots, or features too small for milling. Both methods improve accuracy and repeatability without slowing down tool production.

Stamping dies take a lot of stress over time. If we wait until a tool breaks, we risk damaged parts and costly downtime. That’s why preventive maintenance matters. It helps us catch wear early and keep the die running smoothly. A regular maintenance plan includes cleaning, lubrication, and checking for cracks or loosened components. These steps are simple, but skipping them leads to bigger problems fast.

Punches and die inserts get dull from repeated hits. Dull tools create burrs, misaligned holes, or even press overloads. Sharpening them restores edge quality and keeps parts within tolerance. Cleaning is just as important. Metal dust, oil, and debris can block movement or scratch surfaces. Set a schedule to wipe down components, clean lubrication paths, and remove scrap buildup. During inspections, we check bolts, springs, and guide pins for looseness or damage. It’s better to replace a worn pin today than stop a line tomorrow.

Even a small gap in the die setup can throw everything off. That’s where shimming comes in. Thin metal sheets are added under components to bring everything back into alignment. We also re-check spacing between punches and dies using feeler gauges or dial indicators. If the die is out of parallel, the press might overload one side, causing uneven wear or cracking. Aligning the die after sharpening or part replacement helps keep every stroke consistent.

Some materials last longer than others. High-speed steels or carbides resist wear better than basic alloys. In high-volume jobs, that difference saves money over time. Surface coatings like TiN or DLC reduce friction and stop metal from sticking. They also help keep edges sharper longer. Choosing the right steel and surface finish depends on the part material, press speed, and the type of operation. A good mix extends tool life and reduces sharpening frequency.

Tracking tool life helps us avoid surprises. We can mark each insert with a use count or log press strokes in a tracking sheet. Some shops use sensors or software to alert operators when a component nears its limit. Visual wear indicators are another option. They show how much material has been ground off a punch or die. Planning replacements before failure means fewer rejected parts and better uptime. Lifecycle tracking also helps with budgeting and tool redesigns later on.

Electroplating adds a thin layer of metal to the surface of a stamped part. We place the part in a solution, apply electric current, and metal ions bond to its surface. It sounds simple, but the results can be powerful. It improves part performance without changing the original design. Electroplating is often used on connectors, terminals, and brackets—basically anything that needs extra protection or better function.

The most common reason we use electroplating is to fight corrosion. A steel or copper part will rust fast if left bare. Add a nickel or zinc layer, and it can last in harsh environments. For electronic parts, conductivity is key. Gold and silver coatings help carry current with almost no loss. That’s why we use them on PCBs, sensors, and high-frequency parts. Some finishes also help with soldering. Tin plating, for example, gives a clean surface that bonds quickly with solder. It’s popular in electronics and appliance parts that need fast, strong joins.

Each plating metal has its own strengths. Nickel is tough and smooth, perfect for general wear resistance. Gold has high conductivity and doesn’t tarnish. Tin helps with soldering and is non-toxic. Zinc fights rust and is used on hardware or automotive parts. Chrome gives a shiny finish and also adds wear resistance. We don’t just pick one for looks. The right finish depends on what the part will face—heat, moisture, voltage, or all three.

| Finish Type | Key Properties | Common Applications |

|---|---|---|

| Nickel | Durable, corrosion-resistant | Connectors, fasteners |

| Gold | High conductivity, no oxidation | Microelectronics, contacts |

| Tin | Solderable, cost-effective | Terminals, PCB components |

| Zinc | Rust protection, affordable | Automotive, structural parts |

| Chrome | Glossy finish, surface hardness | Decorative or moving parts |

Sometimes, we don’t want the entire part coated. Selective plating lets us cover only the surfaces that need protection or conductivity. It saves cost and improves function. We can use masking or reel-to-reel systems to control where the plating lands. Thickness also matters. Too thin, and it wears off too fast. Too thick, and it affects fit or flexibility. Most modern setups use real-time monitoring to control layer thickness down to microns. That means every batch meets exact specs without guesswork.

Every stamped part begins as a digital model. Engineers use CAD tools to define the shape, dimensions, and tolerances. But before building anything, we test the design through simulation. Forming simulations show how the material will behave under pressure. We can adjust the radius, punch speed, or blank shape before cutting any steel. This step helps avoid cracks, thinning, or wrinkles. It’s much faster and cheaper to fix problems here than after the tool is built.

Once the design is locked in, we move to tooling. Machinists create the dies using CNC mills, grinders, and EDM machines. They cut punches, form blocks, guide pins, and lifters from high-grade steel. Precision is key—if just one hole is off, the entire part may fail inspection. To keep tolerance tight, parts are often machined in stages and inspected between setups. Many shops use modular die systems to speed up maintenance or part changeovers. The tooling stage sets the foundation for everything that follows.

In the press shop, the real action happens. Blanking cuts flat shapes out of sheet metal. Piercing adds holes or slots. Drawing pulls the metal into deep shapes, like cups or housings. Each operation must be tuned to the part material and press force. We might run coil-fed strips through progressive dies or load blanks by hand into single-station tools. If the die isn’t set right, even a strong press can’t fix the part. That’s why setup sheets, sensors, and test runs are used before every production batch.

No stamping process runs without checks. Quality teams inspect raw materials, first articles, and random samples during each shift. We measure critical features like hole position, wall thickness, and surface finish. Statistical process control (SPC) helps spot trends before parts go out of spec. We log data from each batch and track press settings, tool wear, and downtime. If something drifts, it’s flagged early. This keeps scrap low and builds confidence in every stamped part that leaves the shop.

Before we design the tool, we choose the right metal. It’s not just about cost. Each material bends, stretches, and reacts to pressure in its own way. If a part needs strength, we might pick high-strength steel. If weight matters more, aluminum or brass could be a better choice. We also check if the material resists corrosion or handles plating well. Some metals crack under tight bends or don’t work well with certain coatings. Picking the wrong one can lead to split edges, poor finish, or failed fit tests.

Bends are where things often go wrong in stamping. If the radius is too sharp, the metal may crack. A good rule is to keep the inside bend radius at least equal to the material thickness. Softer materials like aluminum can handle tighter bends, while harder steels need more room. Flange length also matters. Too short, and the flange may wrinkle or distort. We use standard charts to pick safe bend radii and flange lengths. Planning this early reduces rework and tool modifications later.

| Material Type | Minimum Bend Radius (Relative to Thickness) |

|---|---|

| Aluminum | 1x to 1.5x |

| Mild Steel | 1x to 2x |

| Stainless | 2x or more |

Holes that are too close to an edge or bend line can distort. They might stretch, tear, or lose shape during forming. We keep a safe distance from bends, usually at least twice the thickness of the metal. Tiny holes can also be a problem. If the hole is smaller than the material thickness, it may not punch cleanly. Burrs or tool damage can follow. For best results, we follow standard hole-to-edge ratios and use pilots when needed to ensure alignment.

Not every feature needs ultra-tight tolerances. Holding a ±0.05 mm tolerance on non-critical holes drives up costs. It slows down stamping and increases inspection time. Instead, we talk to customers and decide which areas need precision. Features that align parts or affect function should be tight. Others, like cosmetic slots or drain holes, can be looser. By relaxing tolerances where possible, we extend tool life and reduce setup changes. This keeps production faster and more consistent.

Stamping die design involves precision, careful planning, and efficient material use. In 2025, successful engineers are expected to combine digital tools with hands-on techniques. Early simulation, thoughtful material selection, and durable design have become standard practices. Collaboration with skilled partners often leads to reduced waste and improved production efficiency. Up-to-date knowledge continues to play a key role in achieving consistent and accurate stamping results. If you need further assistance, check our company's metal stamping solutions.

A stamping die shapes or cuts sheet metal into specific parts using high-pressure presses.

Simulations like FEA help predict stress, thinning, and wrinkles before tooling begins.

Common types include simple, progressive, compound, and combination dies, each used for specific tasks.

It prevents tool damage, ensures consistent quality, and extends the life of expensive tooling.

Nickel, gold, tin, zinc, and chrome are commonly used to improve durability and conductivity.