Email: admin@yeeshine-tech.com WhatsApp: +86-13712868936

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-08-12 Origin: Site

In today’s automotive industry, safety, performance, and durability are non-negotiable. Every component inside a vehicle, from dashboard panels to intricate under-the-hood parts, plays a role in delivering a safe driving experience. While drivers often focus on engines, brakes, and tires, another critical element operates behind the scenes: automotive injection molding.

This manufacturing process is responsible for producing thousands of essential components in modern vehicles. From the smallest interior clips to structural parts that endure intense heat and pressure, injection molded components are the invisible backbone of automotive safety and reliability. And when it comes to these parts, quality is not just a competitive advantage—it’s a matter of life and death.

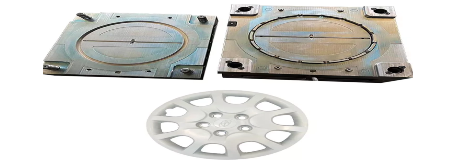

Injection molding is a manufacturing process where molten material—commonly high-grade thermoplastics—is injected into a mold cavity to create precisely shaped parts. In the automotive industry, it’s used for everything from dashboard assemblies to engine bay components, sensors housings, and seatbelt mechanisms.

Poorly made injection molded parts can lead to failures that compromise vehicle safety. Consider the following examples:

Dashboard and Paneling Failures: Weak or brittle panels can crack upon impact, potentially causing injury or interfering with airbag deployment.

Sensor Housing Malfunctions: Faulty housings can expose sensitive electronics to dust, moisture, or vibration, leading to inaccurate safety system readings.

Under-the-Hood Part Failures: Parts near the engine must withstand high temperatures and vibrations. Subpar materials or poor molding quality can cause premature failure, affecting critical systems such as cooling or fuel delivery.

High-quality automotive injection molding ensures that every part—no matter how small—meets stringent safety and performance standards.

The global automotive sector is one of the most heavily regulated industries. Organizations like ISO (International Organization for Standardization) and IATF (International Automotive Task Force) establish quality and safety requirements for suppliers. For injection molded components, this means:

Dimensional Accuracy – Parts must be produced with tight tolerances to fit seamlessly into assemblies without causing stress or misalignment.

Material Integrity – Only materials that meet strength, flexibility, and heat-resistance specifications are acceptable.

Defect-Free Production – Even small imperfections like voids, sink marks, or weld lines can weaken a part’s structural integrity.

Long-Term Durability – Components must maintain performance after years of exposure to temperature changes, mechanical stress, and environmental elements.

Manufacturers who neglect these standards risk producing components that fail prematurely—creating not only warranty issues but potential safety hazards.

Let’s take a deeper look at how quality in automotive injection molding directly impacts vehicle safety:

High-quality molding ensures that the internal molecular structure of the part is consistent and free from weak points. This is especially crucial for parts subjected to stress, such as clips that secure electrical harnesses, brake system components, or seat mechanisms.

Engine bays, brake systems, and fuel-related components must withstand high temperatures and potential exposure to chemicals like oil and coolant. Using inferior materials or improper molding techniques can lead to warping, softening, or cracking—failures that could compromise critical systems.

An incorrectly sized part, even by a fraction of a millimeter, can cause rattling, wear, and eventual part displacement. Precision molding eliminates these risks, ensuring that every component fits perfectly with adjoining parts, maintaining both safety and performance.

In collision scenarios, every vehicle component interacts with safety systems. A poorly molded part could obstruct airbag deployment or break in a way that causes injury. Quality molding ensures that parts behave predictably under stress.

Choosing a low-quality manufacturing process might save money upfront, but it often results in costly failures and safety risks. Here are some common issues:

Brittleness: Caused by incorrect material selection or poor cooling cycles.

Warping: Resulting from uneven cooling or poor mold design, leading to fitment issues.

Weak Weld Lines: Formed when two flow fronts meet without proper bonding, creating fracture-prone areas.

Surface Imperfections: Scratches, bubbles, or rough edges can indicate poor mold maintenance or process control.

Each of these defects can lead to safety concerns, especially in components that support structural or functional systems in vehicles.

Modern automotive injection molding is not just about pressing plastic into molds—it’s a highly technical, precision-driven process that leverages cutting-edge technology. Some key innovations include:

Computer-Aided Engineering (CAE)

CAE software allows engineers to simulate the molding process, predicting issues like air traps, weld lines, and cooling inefficiencies before production begins.

Real-Time Process Monitoring

Sensors inside the molds measure temperature, pressure, and flow rates, ensuring consistency across every batch.

High-Performance Polymers

Advanced materials like PEEK (Polyether ether ketone) and reinforced nylon offer superior heat resistance, strength, and chemical durability for demanding automotive applications.

Automated Quality Inspection

Machine vision systems detect surface and dimensional defects instantly, ensuring that only flawless parts reach the assembly line.

Some manufacturers are tempted to reduce costs by cutting corners—opting for cheaper materials, less rigorous testing, or outdated equipment. However, this often proves far more expensive in the long run due to:

Increased Warranty Claims

Damage to Brand Reputation

Potential Safety Recalls

Loss of Customer Trust

In contrast, investing in high-quality injection molding processes not only prevents these issues but also adds value by enhancing the vehicle’s reliability and longevity.

A leading automotive brand faced repeated failures in a sensor housing located near the engine. The original supplier had used subpar materials and imprecise molding, leading to cracks after only a few months of operation.

Switching to a manufacturer specializing in high-quality automotive injection molding solved the problem. The new parts were produced using heat-resistant polymers, precision-engineered molds, and strict quality checks. The improved design eliminated premature failures, saving the brand millions in potential recall costs and protecting its market reputation.

Partner with Certified Suppliers – Ensure the manufacturer holds relevant ISO and IATF certifications.

Specify Material Requirements – Clearly define the grade, strength, and heat resistance needed for each component.

Implement Rigorous Testing – Include tensile strength, thermal cycling, and impact resistance tests.

Continuous Process Optimization – Use real-time data to refine molding parameters and reduce defect rates.

Invest in Preventive Maintenance – Regularly maintain molds, machines, and quality control equipment to avoid production issues.

In the automotive industry, every detail matters—and automotive injection molding is no exception. High-quality molded components not only keep vehicles running smoothly but also protect drivers and passengers in critical moments. From structural integrity to fitment accuracy, the standards applied in the injection molding process can mean the difference between a safe journey and a dangerous failure.

For manufacturers, suppliers, and designers, the message is clear: Never compromise on quality when it comes to automotive injection molding.

If you’re looking for a reliable partner committed to delivering precision, durability, and safety in every automotive injection molded part, consider exploring www.yeeshine-tech.com. Their expertise in advanced manufacturing processes and dedication to quality make them a valuable resource for companies aiming to meet and exceed industry standards.

content is empty!