Email: admin@yeeshine-tech.com WhatsApp: +86-13712868936

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2024-03-21 Origin: Site

Thanks for customer introduction, Yeeshine got the chance to support the project development of one coupler cover for Canada company, which made by PP+20%GF together with silicon gasket.

PP GF20 material is a reinforcement material composed of PP raw material plus 20% glass fiber. It has good wear resistance, suitable for some applications that require frequent movement or friction.

Here we would like to share with you the injection mold making process.

Basic part information:

● Part size: 180*60*38mm

● Plastic material: PP+20%GF

● Finish: matte finish

● Color: Black

● Production volume: 5K

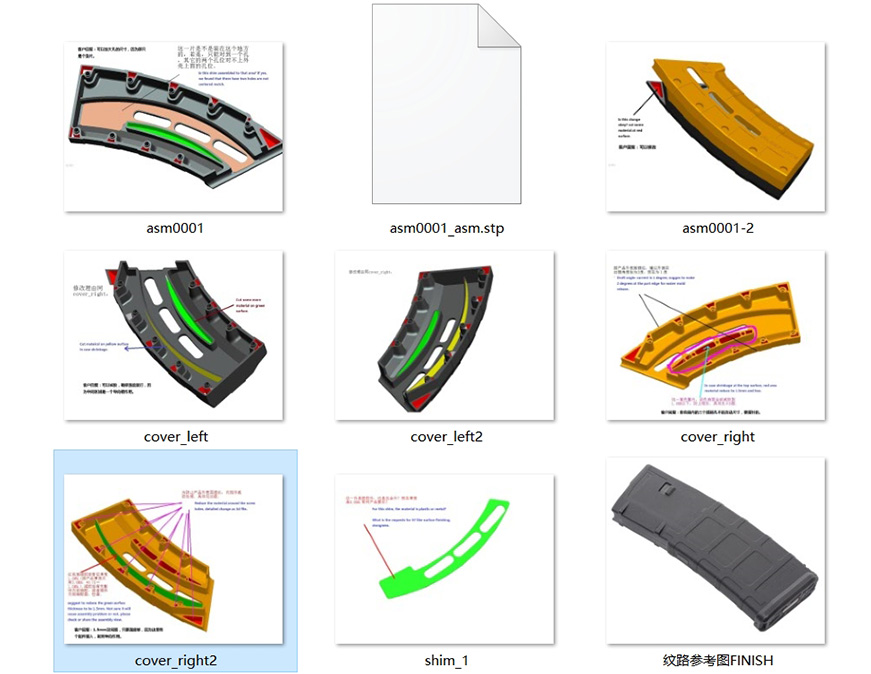

This product consist of three components, top cover, bottom cover and silicon gasket. To save the mould cost, we make one 1+1 cavity layout family mould for top and bottom cover, and then one compression silicon tool for gasket.

Basic mold information:

● Gate type: submarine gate

● Cavity number: 1+1

● Steel Material: S136H

● Shrinkage:1.01

● Mold Dimension: 350*350*290 mm

● Mold Weight: 232kg

Injection mold making process

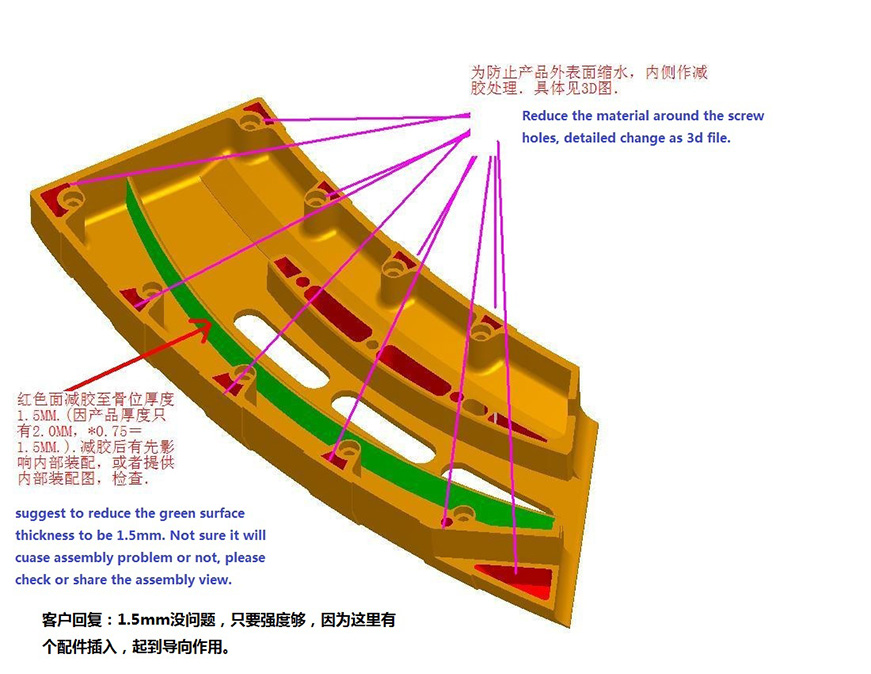

Before making the injection mold, Yeeshine gone through all 2D and 3D files, and then share the suggestions for design optimization and better moulding quality from the points of mould design/making experience. DFM report with our explanation for potential molding issues or assembly concerns.

YEESHINE will make DFM analysis of the plastic part and verify some important information with the customer, like parting line, gate position, ejection, etc. After the verification with the customer, YEESHINE made 2D & 3D design layout of the injection mold.

The injection mold layout as following picture shows:

Injection mold making took 4 weeks, YEESHINE did T1 sample testing on the scheduled time. Below is the T1 trial parts:

Due to the detailed discussion and perfect design drawing, the mould was being machined at a very good performance. Thanks for the timely feedback and no tool change from customer side, we start to make first batch production after T2 trial. That is to say, it takes only 38 days lead time from mould design to first production batch.

Remark by YEESHINE

Injection mold making is a customized process, YEESHINE engineers work closely with customer to understand their requirements and make proper solution to achieve the best possibility,we are not simply a mold manufacture to deliver the parts according to design, we offer solutions and deliver satisfaction.