Email: admin@yeeshine-tech.com WhatsApp: +86-13712868936

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-08-12 Origin: Site

Automotive injection molding is the backbone of modern vehicle manufacturing, producing everything from intricate dashboard components to durable under-the-hood parts. As the automotive industry pushes for lighter, stronger, and more complex designs, manufacturers are turning to advanced manufacturing techniques to elevate both quality and efficiency. High precision, material innovation, and process optimization are no longer optional—they’re essential for meeting safety, performance, and aesthetic demands.

This article explores the advanced technologies and processes that enable manufacturers to achieve superior results in automotive injection molding.

Every molded part in a vehicle, no matter how small, contributes to the car’s safety, performance, comfort, and overall value. From a structural bracket buried deep within the chassis to a sleek dashboard panel that catches the driver’s eye, the quality of injection-molded components can determine whether a vehicle meets—or fails—industry and consumer expectations.

A flaw in molding quality is not just a cosmetic issue; it can lead to performance problems, safety hazards, and expensive recalls. In the automotive industry, where competition is fierce and regulations are strict, a single defective part can cause significant brand damage.

Key reasons why quality matters include:

Safety Compliance – Many injection-molded components are critical to passenger protection. For example, a molded clip holding an airbag in place must perform flawlessly in milliseconds during deployment. Components must meet strict ISO/TS 16949 and IATF 16949 quality standards, as well as regulatory safety requirements, to ensure they can withstand mechanical stresses, temperature fluctuations, and impact forces without failure.

Functional Precision – Modern vehicles are complex assemblies of thousands of parts, many of which interlock or depend on exact alignment. A door panel, for instance, needs to fit perfectly with window seals, handles, and wiring harnesses. Even a fraction of a millimeter in deviation can cause rattles, leaks, or operational failures.

Aesthetic Appeal – Automotive brands invest heavily in interior and exterior design, and molded parts often play a major role in the visual impression. High-end interiors demand seamless finishes, consistent color matching, and texture uniformity. Any imperfections—scratches, sink marks, or color inconsistencies—can detract from the premium feel customers expect.

Longevity – Automotive parts face a wide range of environmental challenges: heat from the engine, ultraviolet radiation from sunlight, moisture, road salt, and exposure to chemicals like fuel and cleaning agents. High-quality molded components are engineered to resist warping, fading, cracking, and chemical degradation over years of service.

Achieving this level of quality is not a matter of chance. It requires expert engineering, precision mold design, advanced polymer selection, and cutting-edge manufacturing techniques. This is where the integration of modern technologies—such as automated quality inspection, multi-material molding, and AI-driven process control—becomes essential for producing consistently superior automotive injection-molded parts.

Material choice is one of the most critical factors in automotive injection molding. Advances in polymers and composites have expanded the possibilities for lightweight yet durable parts.

Materials such as polyetheretherketone (PEEK) and polyphenylene sulfide (PPS) offer superior mechanical strength, chemical resistance, and heat stability—ideal for under-the-hood components.

Incorporating glass or carbon fibers into polymers increases stiffness and strength while reducing weight, supporting the automotive industry’s push toward fuel efficiency and EV range improvements.

Sustainability goals are driving the adoption of biodegradable or recyclable resins, allowing manufacturers to meet environmental regulations without compromising performance.

Even the most advanced material will not yield superior results without a precisely engineered mold.

Computer-aided design (CAD) and computer-aided manufacturing (CAM) ensure molds are optimized for both flow and cooling, reducing defects such as warping, sink marks, or short shots.

Mold flow analysis tools simulate how molten plastic will behave inside the mold, allowing engineers to refine gate placement, runner systems, and venting before production begins.

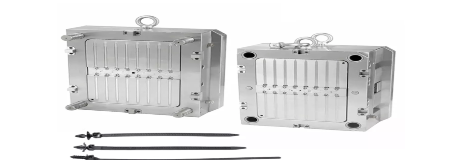

By producing multiple parts in a single cycle, manufacturers increase efficiency while maintaining tight dimensional control.

To achieve superior quality, manufacturers are leveraging specialized molding methods that go beyond traditional injection molding.

This technique uses pressurized gas to hollow out thick sections of a part, reducing material usage and eliminating sink marks while maintaining strength.

By combining different materials or colors in a single mold, manufacturers can create parts with soft-touch grips, integrated seals, or complex aesthetics without secondary assembly.

For extremely small, high-precision components such as sensor housings, micro-injection molding ensures tight tolerances and minimal material waste.

Automation plays a crucial role in ensuring every molded part meets the same high standard.

Robotic Part Handling – Reduces contamination and damage during ejection and packaging.

Automated Quality Inspection – Vision systems detect surface defects, dimensional variances, or color inconsistencies in real time.

Integrated Assembly – Robotic systems can insert components or perform post-molding operations without human intervention, increasing efficiency.

By reducing human error, automation ensures consistent output and traceable quality records.

In advanced automotive injection molding, process control is a science.

Sensor-Embedded Molds – Measure temperature, pressure, and cooling rates for every cycle.

IoT Connectivity – Allows remote monitoring, data analysis, and predictive maintenance to prevent downtime.

Closed-Loop Feedback Systems – Automatically adjust parameters such as injection speed or cooling time to maintain consistent quality.

This level of monitoring ensures that even slight deviations are detected and corrected instantly.

A molded part’s performance is not only determined by its structural integrity but also by its surface quality.

In-Mold Texturing – Creates permanent patterns or finishes during molding, eliminating the need for secondary processes.

Laser Etching – Adds logos, identification codes, or functional markings without damaging the part.

Coating and Painting – Improves appearance, UV resistance, and scratch protection.

By integrating finishing steps into the manufacturing process, manufacturers reduce lead times and enhance product appeal.

With global attention on reducing environmental impact, sustainable manufacturing techniques are becoming integral to the industry.

Material Recycling Systems – Regrind and reuse scrap material without compromising quality.

Energy-Efficient Machinery – All-electric injection molding machines consume less power and produce less noise.

Optimized Cycle Times – Reduces both energy consumption and carbon footprint.

Sustainability also aligns with consumer and regulatory demands, helping automakers maintain a competitive edge.

Automotive injection molding companies that embrace these advanced techniques gain several competitive advantages:

Faster time-to-market due to efficient tooling and automation.

Higher product reliability, reducing warranty claims.

Flexibility to produce complex, customized components.

Improved compliance with global safety and quality standards.

Superior automotive injection molding quality is the result of advanced materials, precise mold design, innovative processing techniques, and robust quality control systems. By integrating automation, real-time monitoring, and sustainable practices, manufacturers can produce components that meet the evolving demands of the automotive industry.

For automakers and suppliers, partnering with a manufacturer that invests in these advanced capabilities can make the difference between meeting industry standards and setting new ones.

If you are seeking high-quality automotive injection molding solutions backed by cutting-edge manufacturing techniques, www.yeeshine-tech.com is a trusted choice. With expertise in precision molding, material innovation, and efficient production processes, the company delivers components that excel in performance, safety, and aesthetics. You can explore their capabilities or contact them directly to discuss your project requirements.

content is empty!